|

||

|

||

|

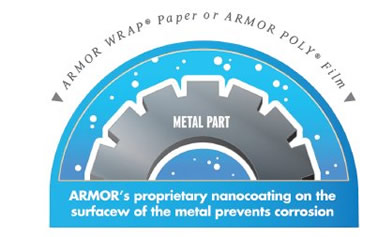

KEY FEATURES IN VCI CHEMICAL FORMULAS Many of us love coffee! When we ask for a cup of “Joe”, aren’t we getting the same thing regardless of where the coffee is from? We all know that is not the case and we have all had some pretty bad coffee at one time or another in our life. The same goes for “VCIs”. Not all VCIs are the same! While the term “VCI” may seem like a generic term, ARMOR VCI Nanotechnology™ is formulated with highly specialized corrosion inhibitors based on ionic salts. When designing a VCI formulation, there are some key things that need to happen to assure that the technology works as needed. In this month’s Corrosion College, we’ve listed the Top 5 key features of a VCI chemical formulation and we have written it in a manner that we hope makes it easy to understand, even for the average “Joe.”

The amount of air flow that metal parts are exposed to determines the length of time that the VCI layer remains in place. Molecules are attracted and deposited on the surface of the metal parts because they are contained in closed packaging and the chemicals reach a saturation point. The minute you expose the surface to open air, the molecules will gradually dissipate. Another key factor in the protection level of the VCI is the warehouse or room where the package is opened. If the room or environment is air conditioned and the relative humidity remains between 40-50% or lower, the unpackaged metal parts should remain rust-free for up to 3 days without seeing rust. Any time RH increases to more than 60%, corrosion can happen in hours or even minutes, meaning you should keep the metal items wrapped in ARMOR VCI during storage. Key Points to Maximize ARMOR VCI Protection AFTER Shipping:

For more information on Armor Protective Packaging®’s full line of corrosion management products, visit the ARMOR website or contact your ARMOR sales representative. |