Shop MPI Products

ARMOR WRAP® MPI VCI Paper

MULTI-METAL RUST PREVENTION PAPER

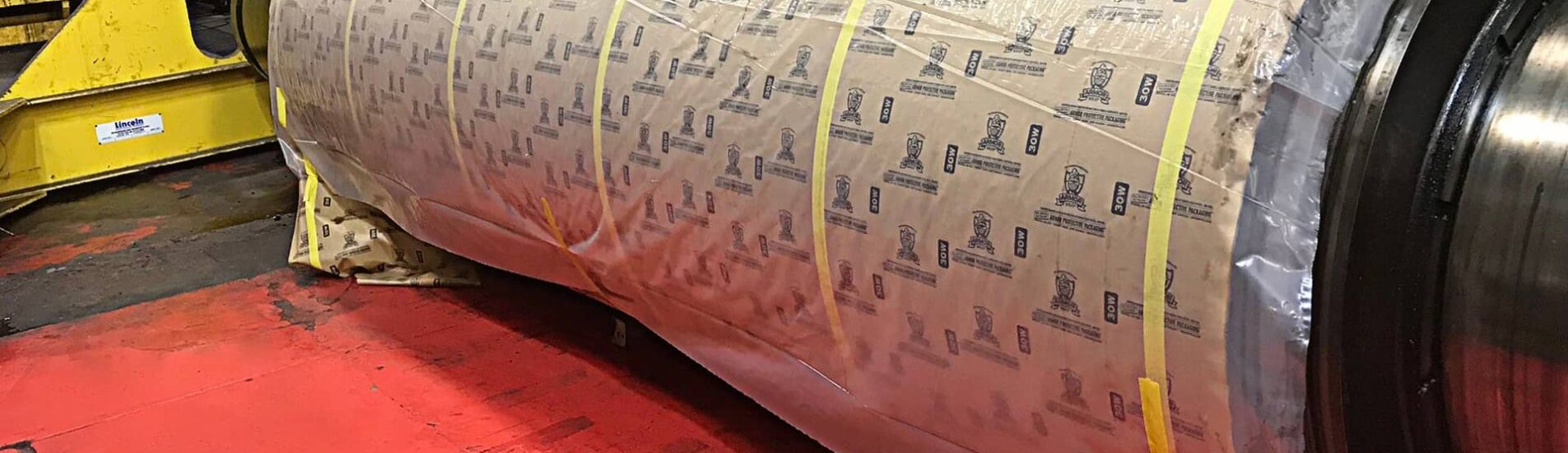

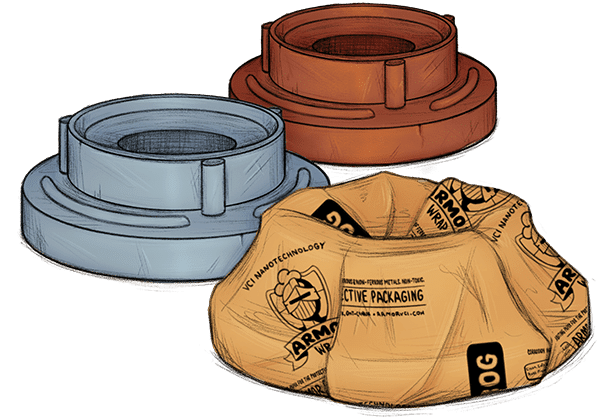

ARMOR WRAP® MPI VCI paper is a multi-tasking, rust-prevention paper for multiple metal types. But, what ARMOR WRAP MPI paper is best at is keeping non-ferrous metals such as aluminum, brass, copper, galvanized, tin, corrosion-freaking-free!

In 2019, ARMOR fine-tuned its MPI formulation and after two years of lab and field-trial testing, it debuted a new-and-improved ARMOR WRAP MPI VCI paper with enhanced corrosion inhibiting performance specifically for aluminum and galvanized metals.

It’s the combination of neutral, pH Kraft paper and ARMOR VCI Nanotechnology® (a.k.a., our “secret recipe” for vapor corrosion inhibitor) that give this rust-prevention paper its “punch.” Once metal parts are wrapped or enclosed in ARMOR MPI paper, the VCIs activate to form a shield of protection on the surface of metal that displaces moisture and repels rust.

ARMOR WRAP MPI is nitrite free, environmentally friendly, recyclable, renewable and it protects both non-ferrous and ferrous metals** from rust and corrosion for up to 3 years. **However, if metal is exclusively ferrous, ARMOR WRAP G formulation is recommended.

ARMOR products are in-stock and ready-to-ship with no order minimums through our ARMOR Stock & Ready® program.

Stock & Ready™ Online Store

ARMOR products are in-stock and ready-to-ship through our ARMOR Stock & Ready® program. Order NOW on the Stock and Ready Online Shop.

Have Questions or Inquiries about ARMOR WRAP MPI?

Features

Technical Specifications:

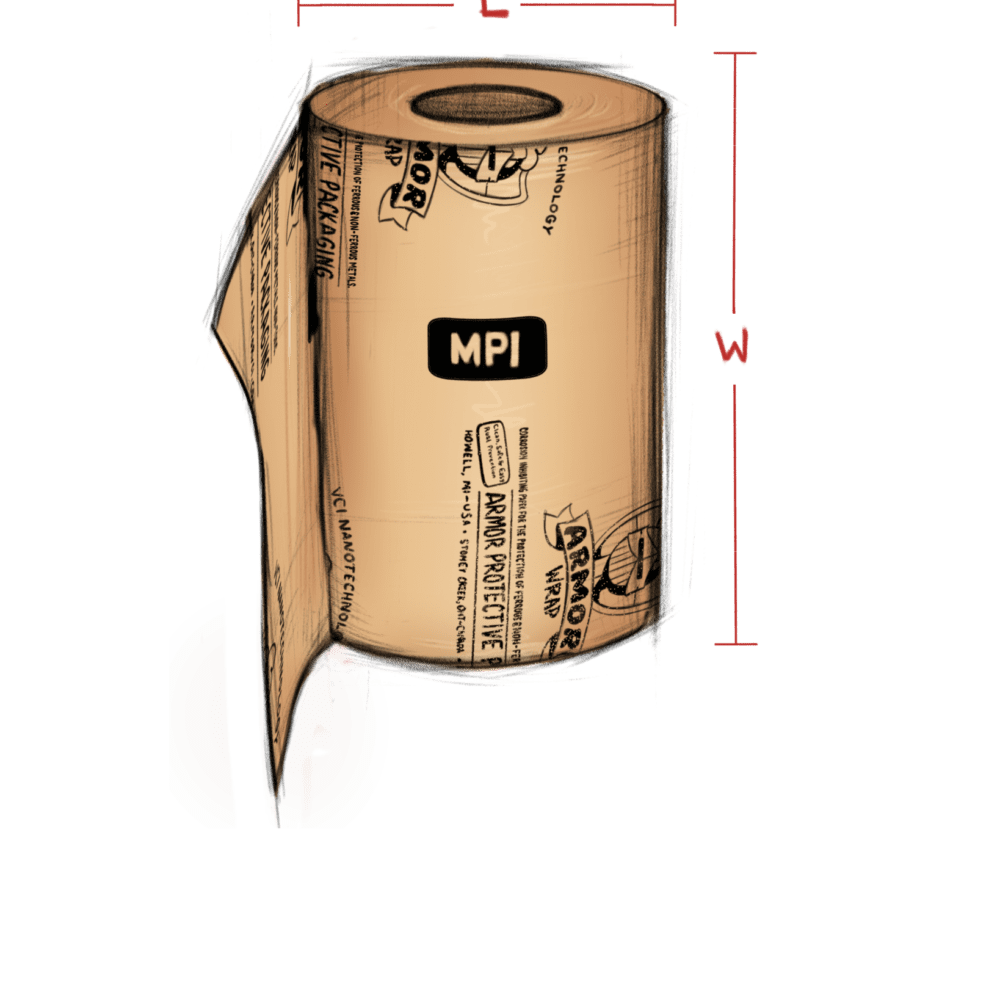

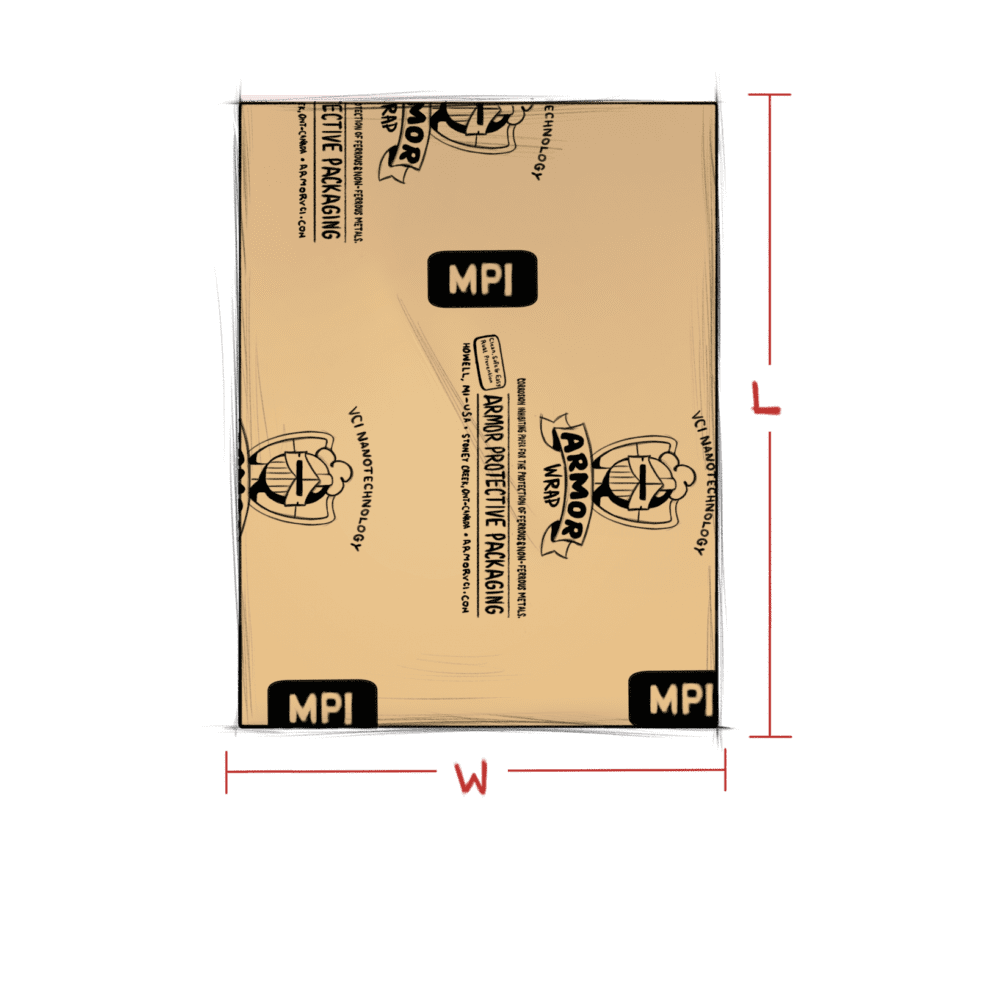

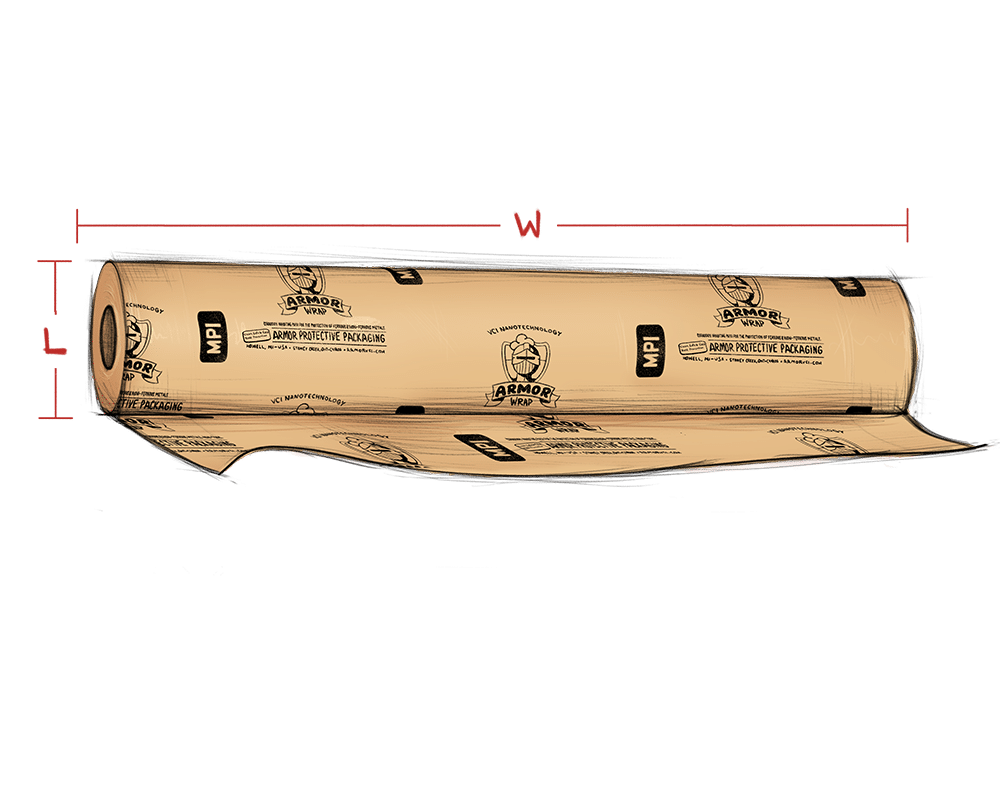

Stock & Ready options:

- 30# MPI formulation in cut sheets and rolls

- Multi-Metal protection – best suited for use with non-ferrous metals

Specs:

- 30# neutral pH, natural Kraft paper

- Specifically formulated for non-ferrous metals

- Wax and poly coated

- MPI formulation is nitrite free

- Custom options also available

Approved By/Conforms:

- FDA for use in equipment packaging

- GLOBAL OEM companies

- RoHS – REACH Compliant

- NACE Std TM0208-2008

- MIL-PRF-3420H and JIS Z 1535 Class 2

Compatibility of ARMOR WRAP with Metals

| Metal to be Protected | ARMOR WRAP Global, Wax, Poly coat(G, W, PC) | ARMOR WRAP Multi-Metal Protection (MPI) | ARMOR WRAP Military Approved (M) |

|---|---|---|---|

| Aluminum | ★★ | ★★ | ⚪⚪ |

| Aluminum Bronze | ★★ | ★★ | ⚪⚪ |

| Aluminum Magnesium alloy | ⚪ | ⚪ | ⚪ |

| Brass | ★★ | ⚪⚪ | |

| Bronze | ★★ | ⚪⚪ | |

| Cadmium | ★★ | ⚪ | |

| Cast Iron | ★ | ||

| Chromium | ★★ | ★★ | ⚪ |

| Constantan | ⚪⚪ | ||

| Copper | ★★ | ★ | |

| Galvanized | ★★ | ⚪⚪ | |

| Lead | ⚪ | ⚪ | ⚪ |

| Molybdenum | ⚪⚪ | ⚪⚪ | ⚪⚪ |

| Nickel | ★★★ | ★★★ | ⚪⚪ |

| Nickel Silver (CU, Ni, Zn) | ★★ | ⚪⚪ | |

| Silver | ⚪⚪ | ⚪⚪ | ⚪⚪ |

| Solder (Pb, Sn) | ⚪ | ⚪ | ⚪ |

| Steel | ★★ | ||

| Tin (Pure) | |||

| Tinned Steel | |||

| Zinc | ★★ | ⚪⚪ |

Galvanized Coating Compatibility Chart

ARMOR WRAP® VCI Papers 30R MPI 30G

| Zinc Galvanized Process Type | Loading Weight | R Contact | R Vapor | MPI Contact | MPI Vapor | Global Contact | Global Vapor |

|---|---|---|---|---|---|---|---|

| Q-Panel Hot Dip Galvanized | 90 g/m2 | ⚪⚪ | ★/⚪ | ||||

| ACT Hot Dip Galvanized unexposed | 70 g/m2 | ⚪⚪ | ★/⚪ | ★★ | ⚪⚪ | ★/⚪ | |

| ACT Hot Dip Galvanized exposed | 60 g/m2 | ⚪⚪ | ★/⚪ | ★/⚪ | ★★ | ||

| ACT Electro Galvanized | 60 g/m2 | ⚪⚪ | ⚪ | ★★ | ★/⚪ | ★ | |

| ACT Zn/Fe Hot Dip Galvanized | 45 g/m2 | ⚪⚪ | ⚪ | ★★ | ★/⚪ | ★★ | |

| ACT Zn/Fe Electro Galvanized | 30-45 g/m2 | ★ | ★ | ★★ | ★ | ★/⚪ |

Compatibility Key

| ★★★ | Complete Protection |

| ★★ | Good Protection |

| ★ | This product will protect this metal from corrosion; however a more suitable formula may be available. |

| ⚪ | Testing is recommended |

| ⚪⚪ | Not Compatible |

Downloadable Resources

Watch These ARMOR Videos & Learn More about ARMOR WRAP®

ARMOR WRAP Saves Continental $1 Million+ Per Year

Armor Protective Packaging helped Continental eliminate rust on shipments of transmission components to Ford, Honda and GM using ARMOR WRAP VCI paper.