ARMOR’s Commitment to Sustainable Corrosion Solutions

Armor Protective Packaging® corrosion solutions were green and sustainable long before it became an imperative. In providing corrosion inhibiting and rust removal products that are safe, clean and easy-to-use, ARMOR provides tremendous environmental and economic benefits while protecting public health, welfare, and the environment.

Given the importance of sustainability, ARMOR has devoted additional resources and an increased focus on both our product line and the way we do business. Here are some of the ways that ARMOR maintains its environmental and sustainability leadership.

The ARMOR 6 R’s of Sustainability

By the most popular definition, sustainability is defined as meeting present needs without compromising the ability of future generations to meet their needs. As it applies to corrosion management, and the shipping and storing of metal products, sustainability means reducing the negative impact on the environment and people through increased use of renewable materials, reduction in the amount of oils and harmful chemicals used, and using less energy in manufacturing and shipping.

Customers large and small are becoming increasingly more aware of their impact on the environment and future generations. Fueled by Walmart’s Packaging Scorecard and Sustainability Index, companies have been implementing sustainable strategies that impact their supplier’s packaging and corrosion prevention decisions. In fact, while the primary and initial goals may have been to preserve the environment and future generations, upon close inspection, many of the ARMOR 6 R’s of sustainability are actually cost savings as well.

6 Ways ARMOR Goes Green

To be clear, ARMOR is not claiming to have the “silver bullet” to save the environment, there is a long way to go for that, for all of us. What we are saying is that we want to be part of the solution. We’re working hard to manufacture corrosion/rust prevention packaging that is clean, safe and easy and just as hard to be an outstanding steward to our beautiful earth. However, there is so much talk on the environment these days, it can be confusing. We’d like to try and clear a few things up. So here it goes!

1. ARMOR PRODUCTS ARE RECYCLABLE

Recycling is one of the best ways to positively impact our environment and our human race. Recycling helps to reduce the pollution caused by waste and reduces the need for raw materials to be used. Huge amounts of energy are needed when making products from raw materials, while recycling requires much less energy and therefore preserves our natural resources. When finished using an ARMOR film or paper, recycle it!

2. RECYCLED CONTENT IS MONEY WELL SPENT

ARMOR utilizes recycled content in our products whenever possible, and we do it without sacrificing their integrity or performance. As recycled resins continue to improve in cleanliness and recycling continues to gain more ground each year, utilizing recycled resin content makes enormous sense.

- ARMOR has a minimum of 30% post-industrial recycled content in all ARMOR POLY® VCI films, these are the same films we use for our VCI (vapor corrosion inhibitor/volatile corrosion inhibitor) bags, sheeting and bonnets.

- ARMOR meets all UK plastic packaging recycled content laws, avoiding expensive taxes to importers.

- Recycling 1 ton of paper (such as ARMOR WRAP®) saves 17 mature trees, 7,000 gallons of water, 3 cubic yards of landfill space, 2 barrels of oil and the energy equivalent of 165 gallons of gasoline.

3. SOURCE REDUCTION SAVES OIL PRODUCTION

Source Reduction (or waste prevention) is the number one recommendation of the United States EPA in their Hierarchy of Integrated Waste Management

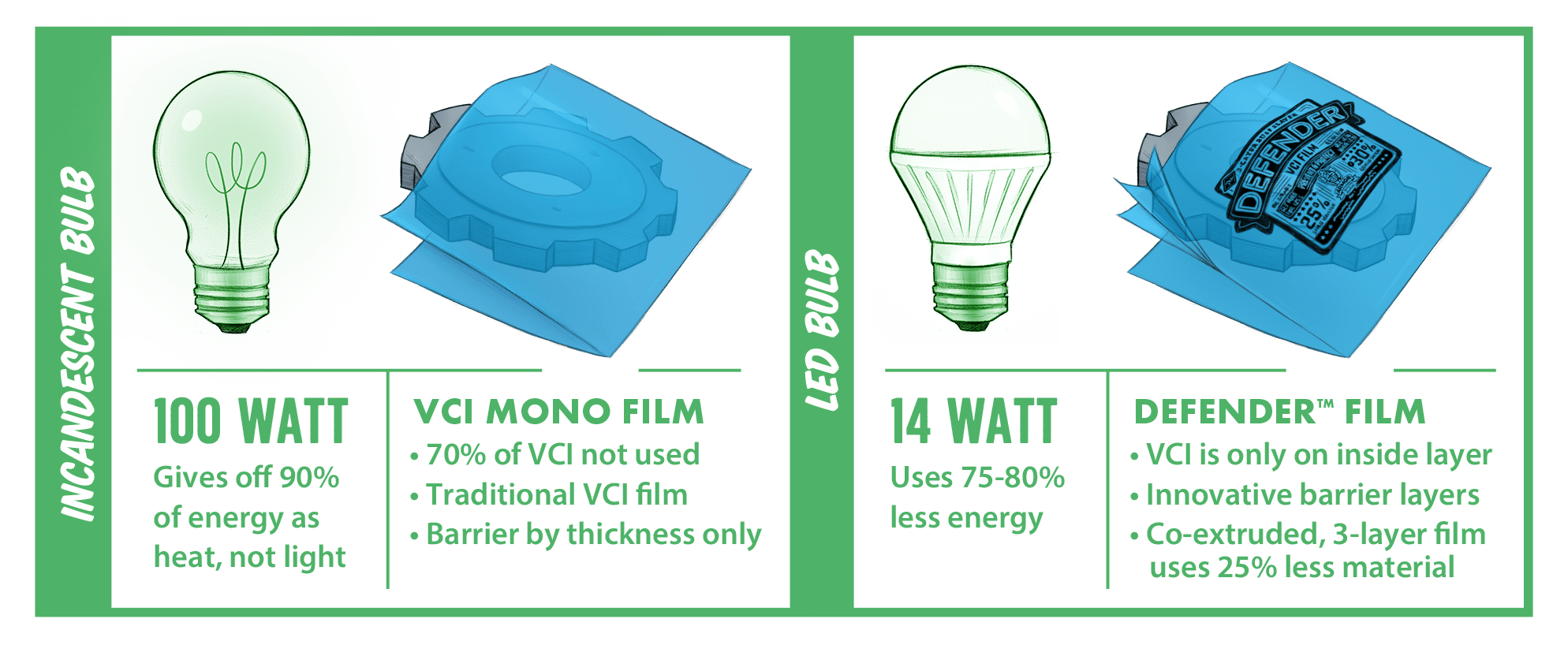

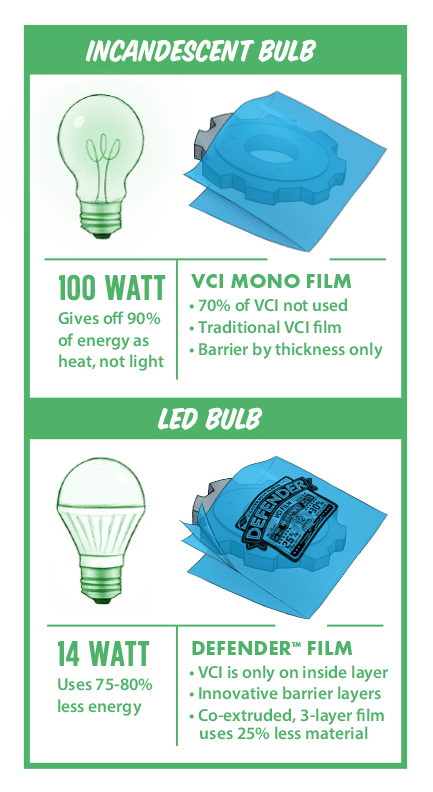

In 2005, ARMOR was the first VCI manufacturer to use innovative engineering to bring multi-layer (co-extruded) films to the market. ARMOR debuted the DEFENDER™, a three-layer film that strategically places VCI on the inside, closest to the metal part, and added unique barriers, allowing the film to be down-gauged by 25-30%. Source reduction at its finest! We like to use the incandescent vs. LED bulb analogy to help explain the concept of source reduction when it comes to mono film vs. DEFENDER™

3. SOURCE REDUCTION SAVES OIL PRODUCTION

Source Reduction (or waste prevention) is the number one recommendation of the United States EPA in their Hierarchy of Integrated Waste Management

In 2005, ARMOR was the first VCI manufacturer to use innovative engineering to bring multi-layer (co-extruded) films to the market. ARMOR debuted the DEFENDER™, a three-layer film that strategically places VCI on the inside, closest to the metal part, and added unique barriers, allowing the film to be down-gauged by 25-30%. Source reduction at its finest! We like to use the incandescent vs. LED bulb analogy to help explain the concept of source reduction when it comes to mono film vs. DEFENDER™

4. THE BIODEGRADABLE FABLE

“Biodegradable plastics are well-intentioned but wrong”

– Jacqueline McGlad, chief scientist at the UN Environment Programme

The Biodegradable Plastics Blacklist: (Or The Knock Against Biodegradable Plastics Today)

- Biodegradable polymer-based films require high temperature and sunlight to biodegrade but these conditions are unrealistic given the current waste and composting systems.

- Its name encourages people to think they actually degrade and promotes ‘single use’ mentality.

- Most are still made from petrochemicals, but other chemicals are added to cause the plastic to break down to smaller pieces – if exposed to the right conditions – making them difficult to recycle.

- Often associated with “green washing,” a marketing technique where a company or a product falsely claims to be eco- or environmentally-friendly.

- If they enter the ocean, they can be worse as smaller plastic pieces are easily ingestible.

At this time biodegradable plastics are not a commercial solution.

5. PAPER – OUR RENEWABLE RESOURCE

ARMOR WRAP® papers are renewable and sustainable. Paper is made from wood, a natural resource that is renewable and recyclable. Paper sustainability in the USA has increased due to the use of renewable biomass and advances in papermaking technology.

- Over 2.5 billion trees are planted in the USA alone each year (millions more grow from seeds and sprout naturally).

- In 2012, over 65% of the paper used in the USA was recovered for recycling.

- In 2014, studies showed 67% of U.S. pulp and paper mills’ energy needs were provided by renewable biomass and fuels.

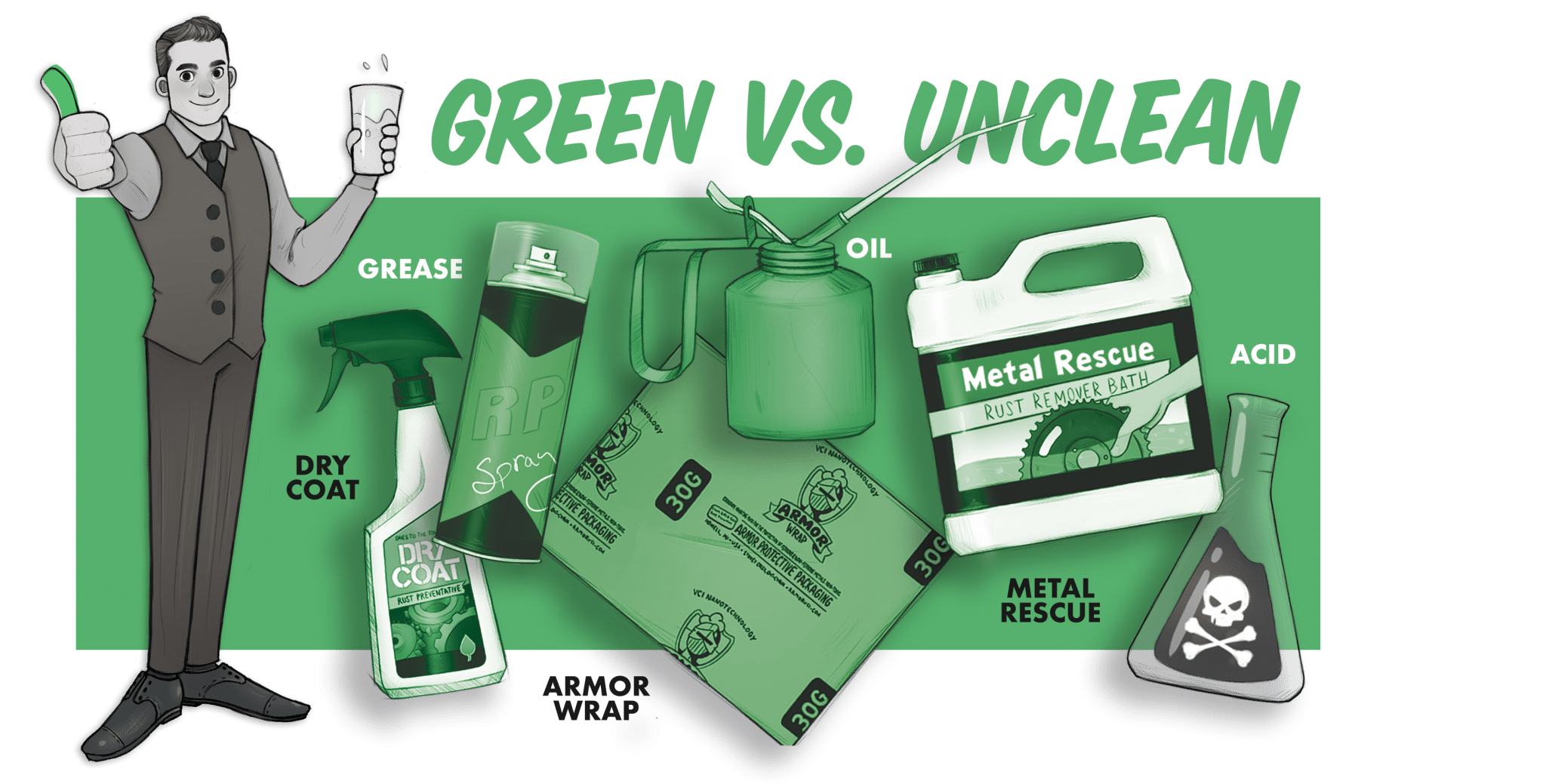

6. ARMOR’S GREEN THUMB

We aren’t new to the “green movement!” We have always made sure our corrosion inhibitor packaging products were clean, safe and easy-to-use and that starts with our water-based technology. Say what? Water? Yes. H2O. Whether it’s ARMOR’s VCI Nanotechnology™ (our “secret formula” for vapor corrosion inhibitors), or our innovative rust remover Metal Rescue® (yes, we remove rust with water…crazy right?), our products must meet the clean, safe and easy “smell test” before they ever hit the market. We are all stewards of this earth and have a duty to do our part at work or at home! Go green!

6. ARMOR’S GREEN THUMB

We aren’t new to the “green movement!” We have always made sure our corrosion inhibitor packaging products were clean, safe and easy-to-use and that starts with our water-based technology. Say what? Water? Yes. H2O. Whether it’s ARMOR’s VCI Nanotechnology™ (our “secret formula” for vapor corrosion inhibitors), or our innovative rust remover Metal Rescue® (yes, we remove rust with water…crazy right?), our products must meet the clean, safe and easy “smell test” before they ever hit the market. We are all stewards of this earth and have a duty to do our part at work or at home! Go green!

Why ARMOR Products are Clean, Safe & Easy

Environment

CLEAN

- Extension of metal parts’ life

- Reduction of energy and raw materials

- Reduction of pollution and waste

SAFE

- Water-based rust prevention

- Reduction of source materials

EASY

- Reuse rather than replacement

- Reduction of energy, waste and raw materials

People

CLEAN

- Water-based rust prevention infused into packaging

- Simple storage & handling

- VCI packaging materials are clean/dry

SAFE

- Prevents health and safety risks

- Eliminates messy oils, greases and solvent-based chemicals

EASY

- Reduction in time and labor to apply

- Once removed from packaging, metal is ready to use

Facility

CLEAN

- Elimination of spills & accidents

- Elimination of labor costs to clean hazardous material

SAFE

- Protects work environment

- Eliminate insurance premiums

EASY

- No set-up, tool or application process

- Eliminates expensive disposal of hazardous materials