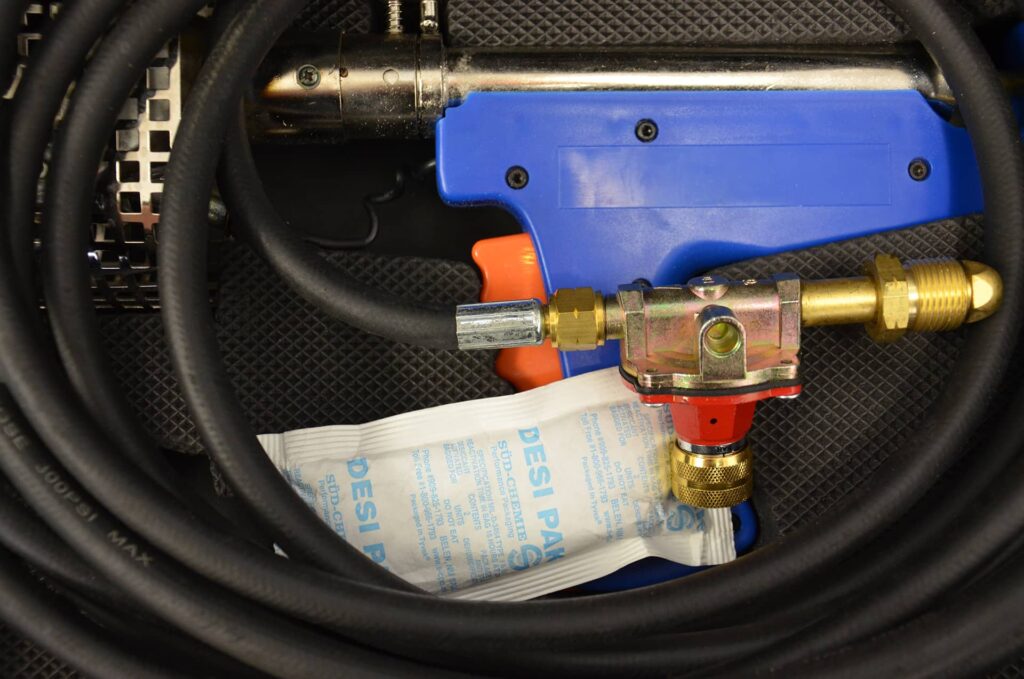

When it comes to managing moisture and preventing damage from humidity, desiccants play a critical role. These materials work by absorbing or adsorbing moisture to keep metal parts and the environments around them dry. One of the most common types of desiccants is silica gel—it’s the small packets often found tucked into consumer goods. But what sets silica gel apart from other desiccants? Here we’ll explore the unique properties of silica gel and how it compares to other desiccants.

Desiccants Explained: How Silica Gel Measures Up

Desiccants are materials that absorb or adsorb moisture from the air to create a dry environment that helps prevent issues like corrosion, mold, and spoilage. Common desiccants include silica gel, clay, molecular sieves, and activated carbon—each with its own unique characteristics tailored to specific applications. Desiccants are especially effective at protecting metal parts from rust and corrosion during storage or shipping.

Silica gel, a granular, porous form of silicon dioxide, is one of the most widely recognized desiccants. It works by adsorbing water vapor onto its surface rather than absorbing it into its structure as a liquid. While all silica gel is a desiccant, not all desiccants are silica gel. Each has a unique chemical composition and structure that affects its ability to manage moisture and remain effective over time.

Learn more about silica gel desiccants >

Desiccants vs. Silica Gel: The Science Behind How Adsorption Works

Silica gel is particularly effective because it is highly adsorbent, meaning moisture sticks to the surface of its particles rather than being absorbed into them. This differs from other types of desiccants, like clay, which absorb moisture and become saturated more quickly.

Silica gel’s adsorption power comes from its extensive surface area, created by millions of microscopic pores, allowing it to trap up to 40% of its weight in moisture. Molecular sieves, another common desiccant, work similarly by trapping moisture in their highly structured pore system. These desiccants are most often used in environments where extremely low humidity is required. This makes them especially useful for protecting metal parts from rust, which quickly accelerates in moist or humid environments.

Advantages of Silica Gel

Silica gel has excellent thermal stability, performing well in both high and low temperatures. It works effectively in environments as hot as 120°F (49°C), while clay desiccants start to degrade at such high temperatures. Silica gel performs well in high humidity conditions, between 60-90% relative humidity. In addition, it is chemically inert, meaning it does not react with other materials, making it compatible with a range of applications including metal parts, sensitive electronics, pharmaceuticals, and food.

Disadvantages of Silica Gel

While versatile, silica gel has limitations. In extremely humid conditions, it tends to saturate faster than other desiccants, such as molecular sieves. Additionally, its effectiveness decreases at very low humidity levels, making it less suitable for environments requiring ultra-dry conditions. In cases where rapid and prolonged moisture absorption is essential, clay desiccants or molecular sieves might be a better choice, as they offer a superior level of moisture control in high-saturation environments.

Comparing Desiccants for Specific Applications

Different desiccants suit different environments, temperatures, and moisture-control needs. Below are common scenarios to help determine when silica gel or other desiccants might be best:

- Consumer Goods Packaging: Silica gel is ideal for small, enclosed spaces, like electronics, food packaging, or shipping or storage for metal parts or components, since it’s compact, non-toxic, and easy to handle.

- High-Humidity Storage: Clay desiccants work well for large storage spaces in humid areas but require more frequent replacement due to their faster saturation.

- High-Temperature Environments: Silica gel is stable at various temperatures, making it a reliable choice for temperature-sensitive items, in contrast to clay desiccants, which degrade with heat.

- Ultra-Low Humidity Requirements: Molecular sieves are best for applications requiring exceptionally low humidity, as they adsorb moisture more quickly than silica gel at lower humidity levels.

Choosing the right desiccant depends on factors such as specific moisture-control needs, environment, and budget. Knowing the strengths and limitations of each type of desiccant can help optimize moisture control across various applications, protecting both products and equipment. To find ARMOR desiccants and other rust-prevention products, visit the ARMOR Stock & Ready™ Online Store.