VCI paper is an excellent solution for protecting metal parts, components, and other metal items from corrosion during storage or shipping. But how long does the rust-prevention power of VCI paper last? Understanding how to extend the lifespan of your VCI paper ensures it is ready when you need it. Let’s take a look at how long you can expect VCI paper to last and how to make it last longer.

How Does VCI Paper Work?

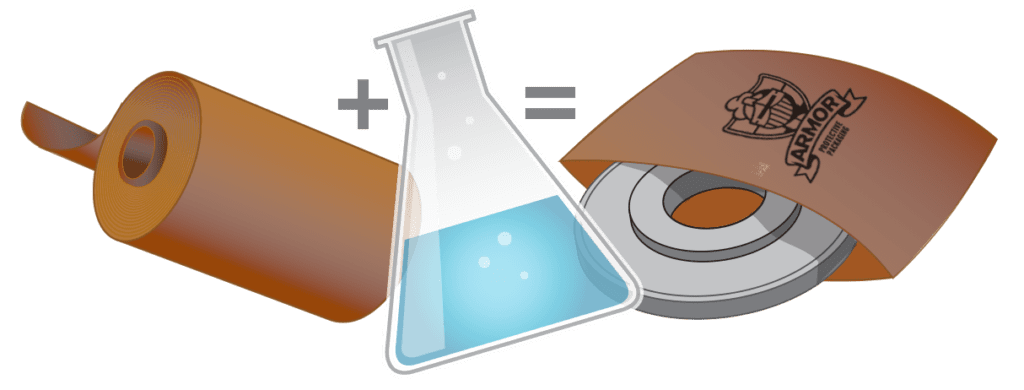

First, let’s review what VCI paper is and how it works. VCI stands for vapor corrosion inhibitor, and it protects metals from corrosion by emitting vapors that form a thin, invisible layer on the metal surface. This layer acts as a barrier against moisture, oxygen, and other contaminants that typically accelerate rust formation.

VCI paper is simply a durable material, like Kraft paper, that is infused with VCI. When metal is wrapped in VCI paper, the vapors are released and gradually settle, forming a protective molecular barrier on the surface of metal that repels moisture and guards against corrosion during storage or shipment.

This technology is effective for a wide range of metals and is particularly useful in applications where traditional protective coatings are impractical. Examples include metal parts with small spaces or intricate designs that are difficult to coat, metal objects that are large or unusually shaped, or metal items where coatings would interfere with their functionality. In addition, VCI paper avoids the labor, dirt, and mess associated with using paints or greases. It is flexible, economical, and easy to use, offering a convenient and effective solution for rust prevention and metal protection.

How Long Does VCI Paper Last?

VCI paper performs differently when it’s actively protecting metal parts versus when it’s in storage, so it’s important to understand how long it stays effective in both scenarios.

VCI paper performs differently when it’s actively protecting metal parts versus when it’s in storage, so it’s important to understand how long it stays effective in both scenarios.

Usage Life vs. Shelf Life

The usage life of VCI paper refers to how long it remains effective while actively protecting metal parts. When VCI paper is wrapped around metal parts and stored in a sealed container, it releases protective vapors that prevent rust. These vapors create a protective barrier around the metal, which is why most standard VCI papers can effectively protect against rust for up to three years. However, the usage life can vary depending on factors such as the VCI formulation, the storage conditions of the wrapped metal parts, and environmental factors like humidity and temperature.

The shelf life of VCI paper refers to how long the paper remains effective while it is in storage, before it is used. Specifically, it describes how long the protective vapors emitted by the VCI paper will stay potent when the paper is not actively protecting metal parts. This is typically the case when it is stored in a sealed package or container, awaiting future use. During storage, the paper is exposed to air, humidity, and light, which can cause the protective vapors to gradually dissipate and decrease its effectiveness. The shelf life of VCI paper is usually up to two years, depending on how well the paper is stored and protected from environmental factors. To maintain its effectiveness, VCI paper should be kept in a sealed container and stored in a cool, dry environment.

At first glance, this might seem a bit flip-flopped, but when VCI paper is in use, the active and constant release of vapor keeps the protective properties strong, ensuring rust prevention for up to three years. In storage, however, the protective vapors gradually dissipate over time. This is why the shelf life is shorter than the usage life—when the VCI paper isn’t wrapped around metal parts, its protective properties slowly fade.

How to Make Your VCI Paper Last Longer

A few tips can help you maximize the longevity and efficacy of your VCI paper while it’s in storage and while it’s in use.

Tips to make your VCI paper last longer while it’s in storage:

- Environment: Keeping your VCI paper in a dry, temperature-controlled environment, such as a warehouse or storage closet, will help it last longer.

- Full seal: Keeping your VCI paper in a sealed container will prevent it from releasing its vapors before it’s needed.

- Check: While it’s a good idea to keep your VCI paper in a sealed container, check on it, (without opening the container,) to make sure the seal hasn’t deteriorated and moisture hasn’t gotten in.

Tips to make your VCI paper last longer while it’s in use:

- Full coverage: Completely covering your metal parts in VCI paper will enhance its effectiveness and help it last longer.

- Full seal: Ensure that your metal parts, while covered in VCI paper, are placed in a sealed container. A secure seal will help keep the VCI paper’s protective vapor close to your metal parts.

- Check: Just like with VCI paper storage, regularly check your metal parts to ensure they are properly wrapped and sealed in VCI paper and are not exposed to leaks or damage. If possible, avoid opening the container unless necessary.

Proper storage and usage of your VCI paper will not only extend its shelf life but also improve its ability to protect your metal parts and components. To learn more about VCI Paper, including ARMOR WRAP VCI Paper, contact us, we can help.