Do you know the most effective methods to prevent rust while your metal parts or components are in storage or shipping? Mastering proper packing techniques is crucial to ensuring your metal items remain rust-free. As experts in rust prevention, we’ve tested hundreds of different techniques and strategies to ensure optimal protection for your metal parts. Use these packaging hacks to keep your metal parts clean and corrosion free while in storage or shipping.

6 Expert Packaging Hacks to Prevent Metal Parts From Rusting

First, it’s important to understand that there are many different ways to prevent rust. The method that is best depends largely on the metal parts or components you’re packaging, including what metals they’re made of, their size and shape, the quantity, and other factors. Of course, the ideal rust-prevention packaging for a very large item, like an engine block or a piece of equipment, will be different from a collection of smaller metal pieces or parts, like a box full of fasteners or brake discs. However, there are a few tips that can universally help with packaging your metal products safely and effectively.

Packaging Tips for Your Specific Parts and Components

If you’re wondering about the best way to package your specific metal items, take a look at our rust prevention guides for packaging. Here, you’ll find helpful application illustrations with tips on how to best package various metal parts and components, including large equipment, bulk parts, small parts in trays, die-cut cavity trays, returnable trays, and much more.

If you don’t see your metal parts packaging configuration represented in our VCI literature section, we have plenty of other resources for you. Our ASK JERRY interactive tool will take you through rust prevention options step-by-step, based on the specifics of your metal parts and shipping or storage conditions. You can also contact us anytime to get expert advice on rust prevention for your situation.

Here are proven packaging hacks to prevent metal parts from rusting in a variety of situations.

1. Don’t Pack Dirty, Rusted, or Damp Parts

This fundamental principle applies universally to all metal items. Never package a metal part or component that is damp, dirty, dusty, or already rusted. Such debris accelerates rust formation and makes it more difficult for vapor corrosion inhibitors (VCI) and other rust prevention packaging materials to protect the surface of metal. Moisture acts as a catalyst for rust, making it harder for VCI to work effectively.

2. Use Gloves When Handling Metal Parts

A common oversight among manufacturers and shippers is neglecting to wear gloves when handling metal parts. The careful wrapping of these items in VCI paper and VCI poly film can be easily compromised if done with bare hands. Human skin can introduce sweat and transfer moisture, oils, and acidity to the metal, all of which accelerate rust formation. To maintain the integrity of your metal parts, always wear clean, cotton gloves during handling.

3. Combine VCI Paper and VCI Poly Film

For optimal protection, use a combination of VCI paper and VCI poly film. Individually wrap items in VCI paper, then place them in a VCI poly bag for a layered approach that provides multiple levels of protection. The porous VCI paper quickly releases VCI molecules, offering immediate corrosion protection, while the VCI poly film acts as a barrier against moisture and oxygen. Together, VCI paper and VCI poly film increase the concentration of VCI molecules within the packaging environment and help regulate moisture levels, ensuring both immediate and long-term rust prevention.

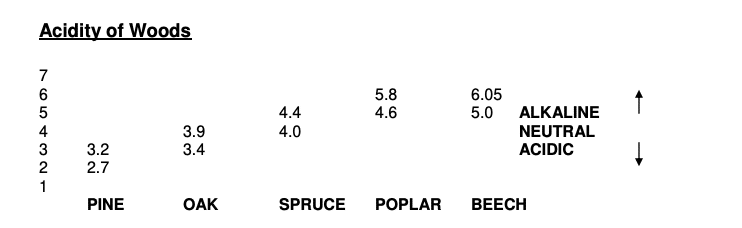

Many types of wood, especially pine and oak, are naturally acidic. These woods are also often used for pallets. If metal parts come into contact with these woods, the acidity can accelerate the rusting process. Instead, separate the metal items from the wooden pallets with a layer of VCI paper or VCI poly film. This rust-prevention packaging hack can significantly reduce rust, which can otherwise appear suddenly and be difficult to manage.

4. Don’t Let Metal Touch Wood Pallets

Many types of wood, especially pine and oak, are naturally acidic. These woods are also often used for pallets. If metal parts come into contact with these woods, the acidity can accelerate the rusting process. Instead, separate the metal items from the wooden pallets with a layer of VCI paper or VCI poly film. This rust-prevention packaging hack can significantly reduce rust, which can otherwise appear suddenly and be difficult to manage.

5. Add Desiccants in Humid Environments

Heat and humidity accelerate rust formation—just a 10°C (50°F) increase in temperature can approximately double the rate of corrosion. When storing or shipping metal parts in humid conditions, include desiccants in your packaging to control moisture. These moisture-absorbing agents provide an extra layer of protection by reducing humidity levels and minimizing the risk of corrosion. Placing desiccants inside packaging or storage containers helps maintain a dry environment, keeping metal parts in optimal condition.

6. Use VCI Materials to Separate Layers of Metal Parts

While it may be tempting to pack multiple metal parts into a VCI bag and seal them in an airtight container, this approach can reduce VCI effectiveness. Stacking or piling metal parts limits the circulation of VCI vapors, leaving some areas unprotected. To maximize protection, place a layer of VCI packaging material between each item or between layers, or wrap each part individually. This ensures comprehensive coverage based on the specific parts or components involved.

Proper packaging is key to keeping metal parts corrosion-free and in top condition, and these expert hacks are designed to simplify the process while maximizing protection. Find all the rust prevention packaging materials you need in our online store, and get them quickly using our ARMOR Stock & Ready™ Program.