Rust and corrosion can turn a minor packaging mistake into a costly disaster. That’s why choosing the right VCI film is crucial. There’s more than one way to make VCI film—but with multiple types available, how do you know which one is best for your needs? Understanding these differences is important, as they determine whether your metal parts and components are protected from rust in a cost-effective way. In this post, we break down the key differences between mono- and co-extruded VCI film to help you make an informed choice.

Understanding VCI Film: The Basics

VCI (vapor corrosion inhibitor) is a class of chemical compounds that release rust-preventing vapors into an enclosed space. It is added to packaging materials like polyethylene to create VCI film and bags that protect metal parts from rust and corrosion. This process works by releasing VCI molecules that create an invisible protective layer on metal surfaces, preventing moisture and oxygen from causing oxidation and corrosion.

While all VCI films serve the same purpose, the manufacturing process impacts their effectiveness. The two primary types of VCI film are mono-extruded and co-extruded, each with distinct structural and performance differences. Before we dive into these differences, let’s first define what we mean by mono-extruded and co-extruded film.

Not sure which VCI is best for your metal parts or components?

Chat with the rust prevention experts >

Mono-Extruded Film vs Co-Extruded Film

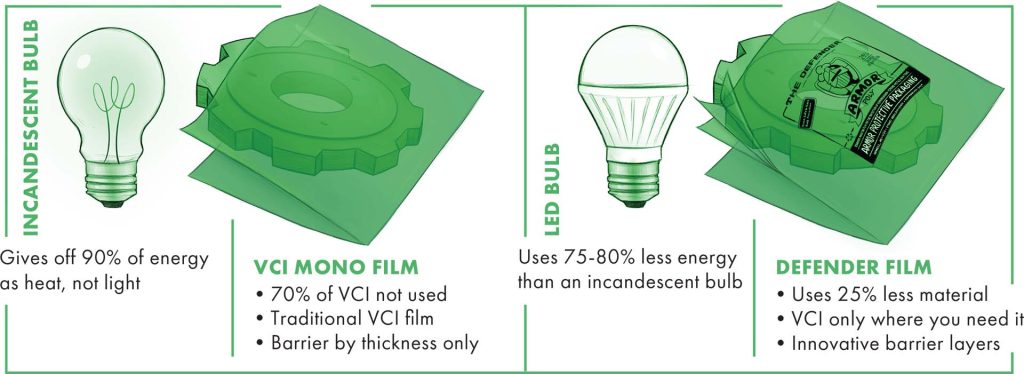

Mono-extrusion and co-extrusion are two methods of producing plastic film. Mono-extrusion produces film from a single layer of polyethylene, where corrosion inhibitors are evenly blended throughout the film. This method ensures uniform VCI distribution, providing reliable rust prevention for general-purpose packaging of metal parts.

Co-extruded VCI film, on the other hand, consists of multiple layers fused together, each serving a specific purpose. Co-extrusion allows for a more durable and functional VCI film, as each layer can be made from different materials to serve distinct purposes. For instance, the outer layer can be designed for enhanced durability and puncture resistance while the inner layer contains the VCI that releases its rust-preventing vapors to protect metal parts. Co-extruded VCI film offers improved protection and performance.

The Differences Between Mono- and Co-Extruded VCI Film

Now that we have a good understanding of the different types of extrusion and VCI, let’s take a closer look at the specific differences between mono- and co-extruded VCI film and why these distinctions matter for effective rust prevention.

When it comes to VCI film, thicker doesn’t always mean better protection. Mono-extruded VCI film consists of a single, thick layer, while co-extruded VCI film is made up of multiple engineered layers, each serving a specific purpose to optimize the film’s strength, flexibility, and corrosion protection of metal parts.

Total Protection

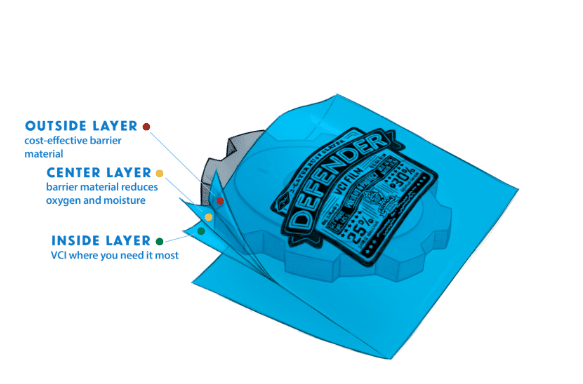

For example, ARMOR’s DEFENDER® co-extruded VCI film is constructed with three distinct layers:

- The innermost layer contains VCI, positioning the rust-prevention vapors closest to the metal parts.

- The middle and outer layers are specifically formulated for durability and barrier protection, increasing resistance to moisture, oxygen, and punctures.

This multi-layer approach ensures stronger, longer-lasting corrosion prevention to protect metal parts in demanding environments.

Thickness: More Isn’t Always Better

DEFENDER® VCI Film takes full advantage of the co-extrusion production process, delivering equal (or better) durability while using 25% less material—reducing plastic waste without sacrificing performance. Compared to a similar single layer, mono-extruded VCI film, the DEFENDER’s multi-layer design enhances puncture resistance and flexibility, making it ideal for protecting metal parts that require a lightweight yet durable protective barrier.

Environmental Impact: A More Sustainable Choice

Packing large metal parts or high volumes of metal items can generate significant plastic waste. Effective corrosion protection is crucial, especially during overseas shipping, but rust-prevention packaging is often discarded after delivery.

ARMOR’s co-extruded DEFENDER VCI Film delivers the same corrosion protection using 25% less material—reducing waste and resource consumption without compromising its rust prevention performance. Plus, it contains a minimum of 30% recycled content, making it a more sustainable choice.

At scale, these savings can be substantial. For example, one ARMOR customer prevented 500,000 lbs of plastic from being used or sent to landfills simply by switching to co-extruded VCI film. They receive the same or better rust protection for their metal parts while minimizing waste.

To find out how much plastic waste you can save, try our sustainability calculator—it’s an easy way to see how much you could save by switching to ARMOR’s co-extruded DEFENDER VCI film.

Making the Right Choice for Your Packaging Needs

Choosing between mono-extruded and co-extruded VCI film depends on your specific application. If durability, efficiency, and sustainability are priorities, co-extruded VCI film is the clear winner.

If you’re interested in learning more about how ARMOR’s DEFENDER® film can enhance your rust prevention strategy while reducing plastic waste, download the product overview or contact an ARMOR Eradicator of Rust today for more details.