Summer is often a time when manufacturing plants, including those dealing with metal, metal parts, and equipment, schedule temporary shutdowns for changeovers and preventative maintenance. The intent of this scheduled downtime is to ensure that production machinery is inspected, repaired, and properly maintained to ensure optimal performance and safety. However, the increased heat and humidity that is a reality of a summer shutdown can place metal and metal parts in the danger zone for rust and corrosion.

A comprehensive plan to protect metal parts, components, and equipment from corrosion should be a key part of any summer shutdown pre-planning process. As the saying goes, “an ounce of prevention is worth a pound of cure” and these words of wisdom are especially true when it comes to rust prevention.

ARMOR VCI: Next-Level Rust Prevention

Armor Protective Packaging® offers a range of VCI (vapor corrosion inhibitors) rust-prevention products designed to protect metal parts from rust and corrosion, especially during the hot and humid conditions of summer. VCI is a class of chemical compounds that emit rust-inhibiting vapors into an enclosed air space. When VCI is combined with materials like Kraft paper or polyethylene film, it creates easy-to-use rust-prevention packaging that protects metal parts from corrosion, even in hot and humid conditions.

Traditional rust-prevention methods, such as oils and grease, create a physical barrier on the surface of metal. However, they are labor-intensive to apply and often must be removed before metal parts can be used.

ARMOR’s proprietary VCI Nanotechnology™ is different. It works on a molecular level to prevent rust. When metal parts are wrapped or enclosed in VCI packaging, the VCI emits its rust-inhibiting vapors that settle on the surface of metal to form a protective layer that is only a few molecules thick. This VCI shield displaces moisture and other corrosion-causing contaminants, keeping metal clean and rust-free.

The mixed inhibitor technology in ARMOR’s VCI formulation gives it the unique ability to “self-adjust” the level or concentration of its vapors in response to changing summer weather conditions. As temperatures and humidity levels rise, vapor pressure increases, releasing more VCI vapors to protect metal surfaces. Or, when conditions cool, the vapor pressure decreases to maintain an effective level of protection.

Summer’s Corrosion Culprits: Factors Affecting Rust Formation

Did you know that there are several environmental factors during summer that contribute to increased corrosion risk? These factors include:

- High temperatures and humidity: When the air is warm, it can hold more moisture, causing humidity levels to rise. This moisture can condense on cool metal surfaces, which promotes the formation of rust.

- Increased thunderstorms and rainfall: Summer often brings more frequent and intense thunderstorms, exposing metal surfaces to prolonged moisture.

- Air pollution: Pollutants in the air can combine with moisture to form acids, speeding up the corrosion process.

- UV rays: Prolonged exposure to sunlight can degrade both protective coatings and the packaging materials used in VCI products, reducing their effectiveness in preventing corrosion over time.

These factors highlight the importance of proactive rust prevention strategies during summer to protect metal parts, components, machinery and equipment. VCI products not only prevent rust, they also enhance the durability and performance of metal parts, while minimizing the costs and downtime associated with corrosion.

Better Yet, Using VCI is “No Sweat”

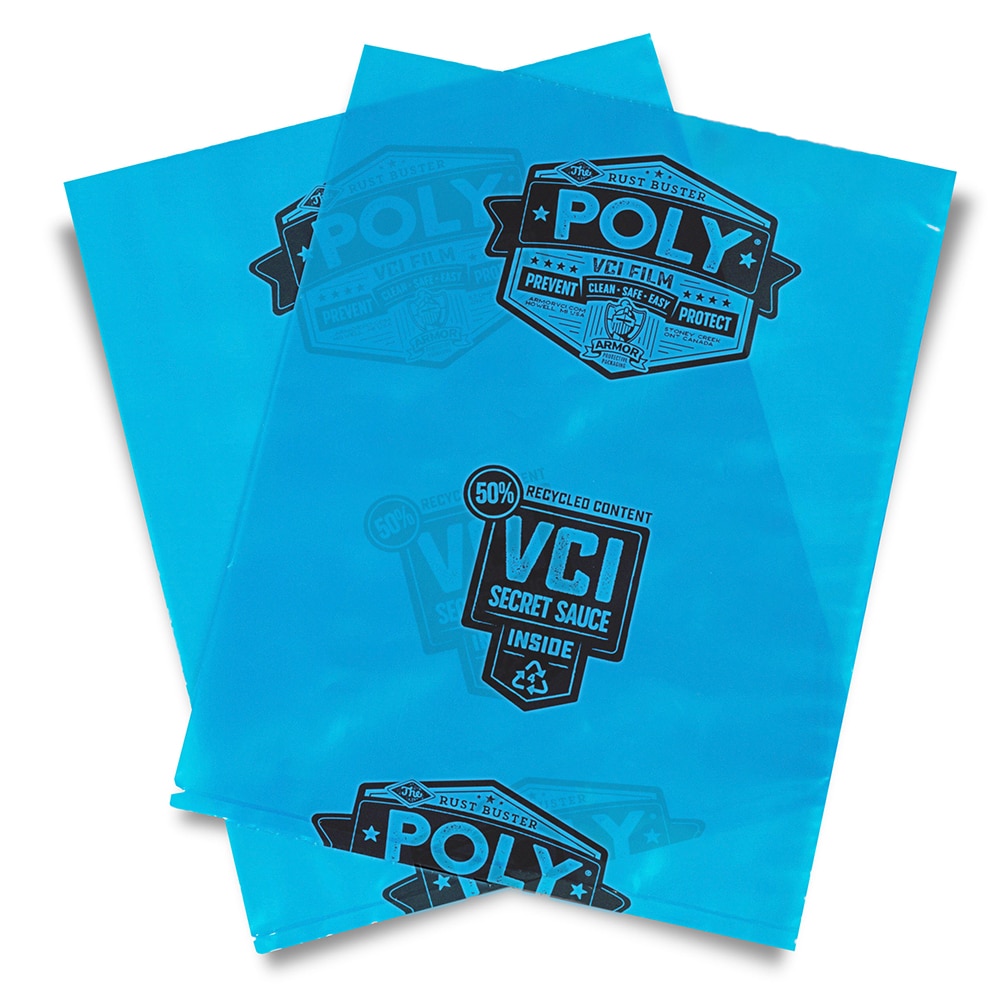

Protecting metal parts, components or machinery during production downtime with VCI rust-prevention packaging is straightforward and mess-free. Products such as ARMOR WRAP® VCI Paper and ARMOR POLY® VCI Film are clean, safe and easy to apply. Simply wrap, enclose, or cover metal parts in rust-prevention paper or film and the VCI does the rest. VCI packaging saves time and effort—metal parts removed from VCI packaging are immediately ready for use without cleaning, wiping, or degreasing. In addition, ARMOR VCI does not alter metal properties – it does not change the appearance, weight, or feel of metal parts, and it does not compromise metal surface coatings or treatments.

To Maximize the Benefits of VCI Packaging, Follow These 4 Tips for VCI Application:

- Clean and Dry Before VCI: VCI protection is most effective when the surface of metal parts is clean and free of germs, bacteria, or other contaminants. Clean and dry metal parts before they are wrapped/enclosed in VCI packaging.

- Pack Parts Immediately: Package metal parts immediately after processing, manufacturing or cleaning and before dust, moisture or other contaminants degrade the metal’s surface.

- Use Protective Gear: Human hands/fingerprints contain moisture, oils and acidity that can be directly transferred onto metal parts and cause corrosion. Clean, cotton gloves should always be worn when handling metal parts to prevent transfer from skin to metal.

- User Training Prevents User Error: Train and educate employees on the proper use of VCI products to ensure they are applied correctly and consistently.

By integrating ARMOR VCI products into your summer shutdown strategy, you protect your metal parts, your bottom line, and ultimately, your reputation. Make rust prevention a key part of your summer shutdown plan to ensure you’re ready when it’s time for production to start up.

Armor Protective Packaging® and its team of “Eradicators of Rust” have more than 40 years of experience in producing rust prevention and removal products that are designed to protect metal parts from corrosion while they are in process, in storage, or in transport. All ARMOR VCI rust-prevention products are clean, safe, easy to use, and effective – whatever the reason and whatever the season.

Shop Poly Products

Related News

To learn more about ARMOR VCI products, check out this episode of Arrusted Development – How to Prevent Rust in High Humidity Conditions.

Take action to protect your metal parts, components, machinery, and equipment from Mother Nature’s steam bath and the corrosion that results.