Armor Protective Packaging® manufactures rust prevention packaging that is designed to keep metal parts clean and corrosion free while in process, in storage or in shipping. Whether it is ARMOR WRAP® VCI paper, ARMOR POLY® VCI film, VCI foam emitters or our dual desiccant/emitter SMARTY PAKs, you can maximize the rust-prevention “powers” of VCI with one simple step – proper storage.

VCI, which stands for vapor corrosion inhibitors, are a class of chemical compounds that can be infused or combined with materials such as Kraft paper or poly film to create rust prevention packaging for metal parts. When metal parts are wrapped or enclosed in VCI packaging, it emits VCI vapors that form a layer of protection on the surface of metal to block moisture, dirt/dust and other contaminants that cause corrosion.

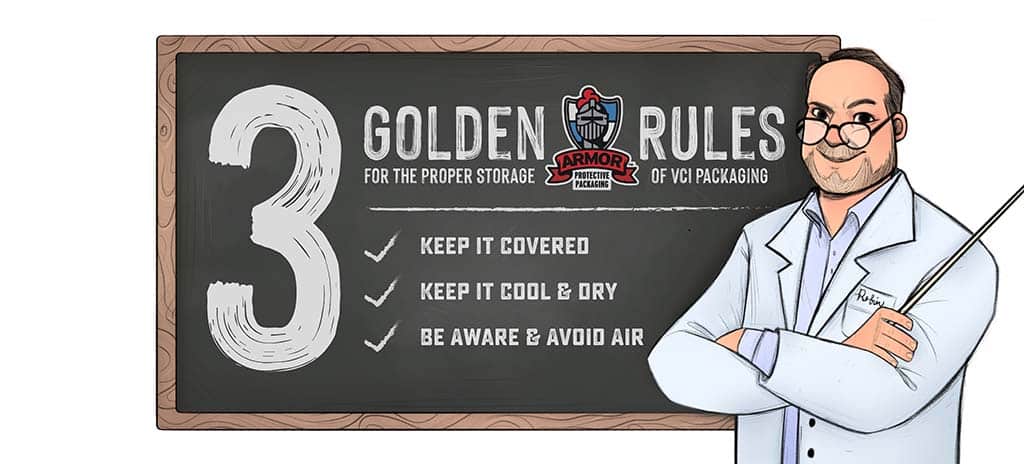

Because VCI is engineered to release its rust-preventing vapors into an enclosed air space, it is important to keep new and unused VCI products tightly wrapped and “contained” to ensure that the VCI remains in the packaging. Follow ARMOR’s 3 Golden Rules for the Proper Storage of VCI Packaging to protect the “protector” (meaning your VCI) and it will do the same for your metal parts.

Rule #1: VCI — Keep It Under Wraps

Safeguard your ARMOR VCI products from damage or contamination by keeping them in their original packaging and under cover or inside a container. Exposure to water, moisture, dirt or dust can result not only in physical damage to packaging materials, but it can also reduce or erode the effectiveness of VCI as well. To preserve the rust-eradicating power of your VCI and ensure the vapors remain in the packaging, securely store in a bin, container, case, crate, sealable box or bag, canister or “vessel” of your choosing.

Rule #2: VCI – Keep It Cool and Dry

How you store VCI packaging products is important, but where you store them is just as important to keeping them at their rust-preventing best. Store VCI packaging (in its original packaging) in an environment that is cool, dry and away from ultraviolet (UV) light. Excessive heat, high humidity and exposure to UV light can cause VCI products to crack, degrade or disintegrate.

As temperature and humidity levels increase, the rate of the volatilization of the chemicals contained in the VCI packaging also increases, which ultimately can cause a decrease in the performance of VCI. If possible, store ARMOR VCI products inside and away from the elements at temperatures of 40° – 110°F (5° – 43°C).

Rule #3: VCI Usage – Be Aware and Avoid Air

Minimizing your VCI packaging’s exposure to air is one of the best ways to maximize its longevity and effectiveness. For best results, do not leave ARMOR VCI products out in an open environment, either indoors or outdoors.

When using VCI packaging materials, practice the FIFO method (first in, first out) where those VCI products purchased first are the first to be used. In addition, work in small quantities; pull out only what is needed and reclose packaging during downtime or at the end of the day.

If using ARMOR WRAP® VCI paper that has been in storage for an extended period of time or exposed to air for 24 hours or more, remove and dispose of the outer layer from a roll or several of the top sheets from a stack before use.

Proper storage of new or unused VCI packaging products isn’t complicated, but it is essential to ensuring that the optimal level of VCI is maintained. By simply following the 3 “golden rules” for storage, you can protect your investment of VCI packaging so that it can, in turn, protect your investment of metal parts.

To learn more about ARMOR’s line of VCI rust prevention products visit the ARMOR website or contact your ARMOR sales representative.