Protecting metal parts from corrosion while in production, in storage or in shipment is a challenge. Corrosion’s damaging effects can strike at any point in the manufacturing process:

• Newly machined parts are highly susceptible to flash rust or corrosion because the metal’s surface is fresh and unprotected;

• Metal parts in storage may be exposed to moisture, salt, airborne chemicals or contaminates; and

• Metal parts in shipment or transport are likely to experience fluctuations in temperature and humidity.

To keep your metal parts corrosion-free every step of the way, wrap them in protection and wrap out rust with an anti-rust paper like VCI WRAP. Made from Kraft paper that has been infused with Vapor Corrosion Inhibitors (sometimes referred to as Volatile Corrosion Inhibitors), this rust prevention paper is specifically designed to protect metal parts from corrosion while in process, in storage or in transport.

How VCI Paper Prevents Rust

VCI is a class of chemical compounds that emit corrosion-inhibiting molecules into an enclosed air space. When VCI is combined with Kraft paper, the result is a anti-rust paper packaging material that prevents rust.

When metal parts are wrapped or enclosed in VCI paper, the VCI vapors are released and they attach to the surface of metal to form an undetectable shield of protection that keeps dirt, water, moisture and corrosion-causing contaminants away from metal.

Traditional rust preventatives — such as oil or grease – protect metal with a physical barrier that is messy and labor intensive to apply. VCI, on the other hand, protects metal with a molecular barrier that is non-detectable and does not change the look, weight or feel of metal parts, and it does not compromise metal surface coatings or treatments.

Better yet, once metal parts are removed from VCI paper, the VCI dissipates leaving metal parts ready for immediate use. The added work of cleaning or degreasing that is required from rust preventative oils and greases is eliminated!

VCI Anti-Corrosion Paper Makes Rust Prevention Easy

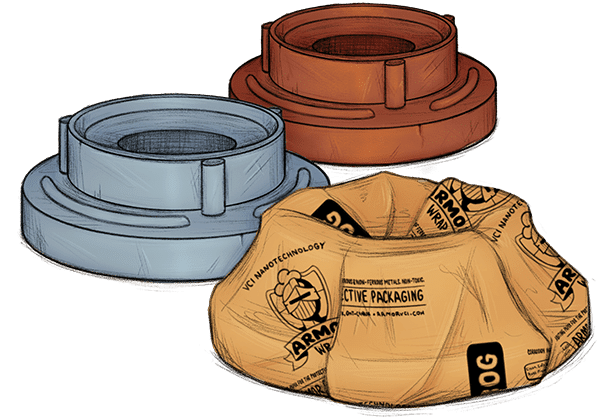

VCI anti-corrosion paper is designed to keep both ferrous and non-ferrous metals rust free, and thanks to the inherent flexibility of paper, it is ultra-easy to apply and ideal for most sizes and shapes of metal parts. To use, simply wrap metal parts or interleave VCI paper between layers of metal parts in storage containers or shipping crates.

Some VCI papers, such as ARMOR WRAP®, are not only manufactured in a variety of sizes of cut sheets or rolls, but they are also available in different formulations such as global, multi-metal and military-approved. Many also offer the option to add a coating to the VCI paper such as a wax or poly to increase protection against moisture, grease or oils, or scrim for added durability and tear resistance.

The Benefits of VCI Paper

Rust prevention does not have to be a “dirty job.” Use VCI paper to eliminate the time, labor and mess of applying and removing rust preventative oil or grease. In addition, VCI paper sheets or rolls simplify the application process while keeping it clean, dry and effective. Work smarter, not harder with VCI paper and its many benefits:

• CLEAN: no messy oils or grease to apply or remove

• SAFE: VCI paper is environmentally friendly, recyclable and re-pulpable

• EASY-TO-USE: flexible packaging material; easily forms around differing shapes and sizes of metal parts

• WORKS FAST: paper releases VCI quickly, which allows VCI to form its protective shield on the surface of metal parts fast

• EFFECTIVE: protects metal from corrosion for up to 3 years