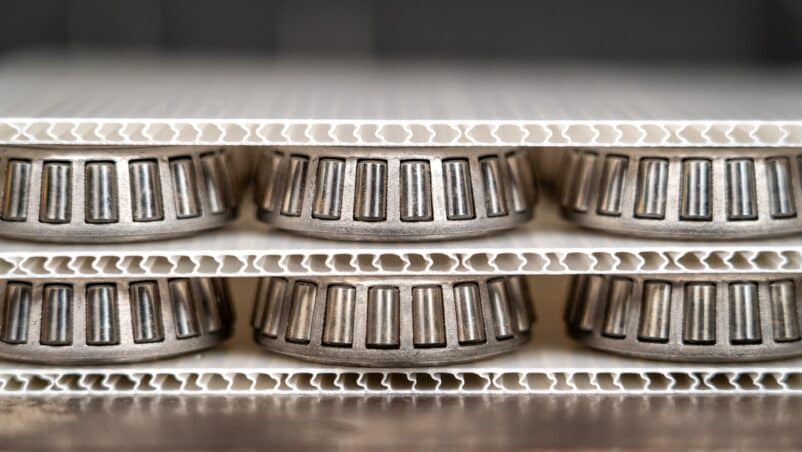

Protect Metal Parts in Spring: VCI and Desiccant for Rust Prevention

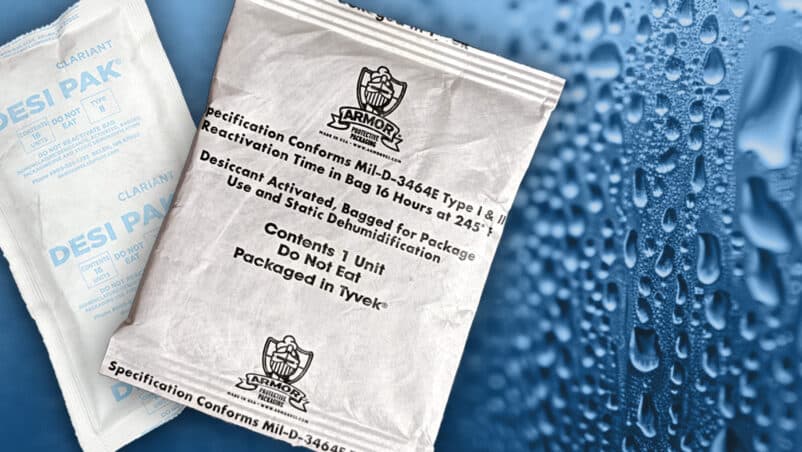

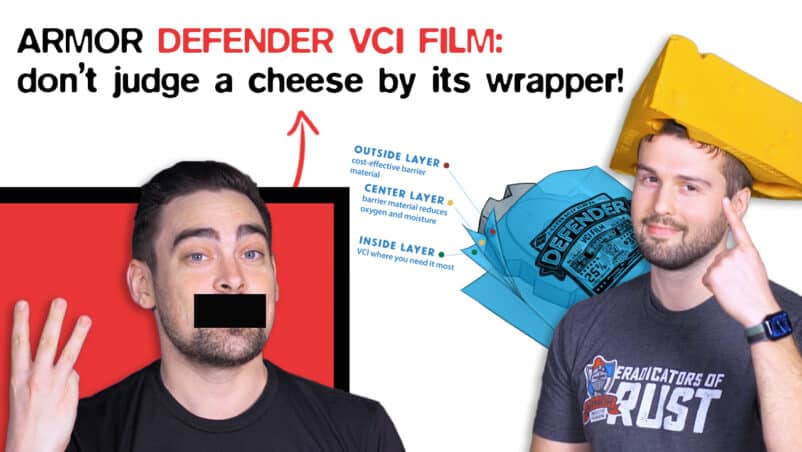

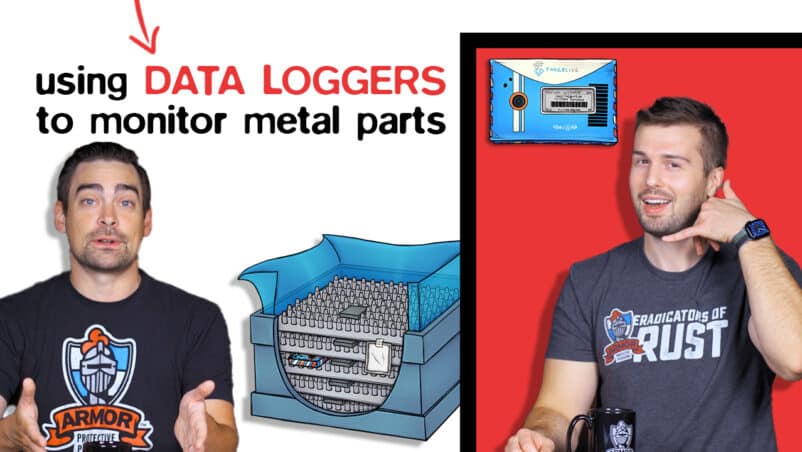

As spring brings its mix of warm days and cool nights, metal parts face an increasing risk of corrosion due to condensation. ARMOR VCI and desiccant products keep metal parts clean and rust-free year-round, no matter the reason or the season. Read more